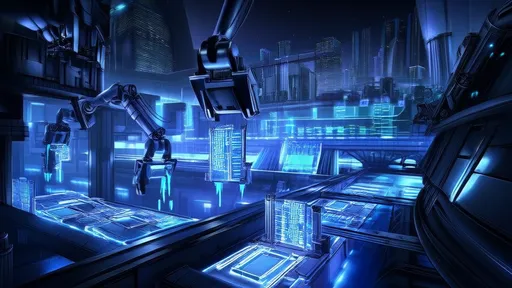

The field of chemical synthesis is undergoing a quiet revolution as robotic researchers begin to autonomously optimize reaction pathways with minimal human intervention. These AI-driven systems are not merely executing pre-programmed instructions but are actively designing, conducting, and refining experiments in pursuit of more efficient chemical processes. What began as laboratory curiosities have evolved into sophisticated platforms capable of outperforming human chemists in certain optimization tasks.

At the heart of this transformation lies the integration of machine learning algorithms with robotic laboratory equipment. Unlike traditional automation, these systems employ active learning - they analyze experimental outcomes in real-time and use this data to determine the next most informative experiments to perform. This closed-loop approach allows for rapid exploration of chemical parameter spaces that would take human researchers months or years to investigate thoroughly.

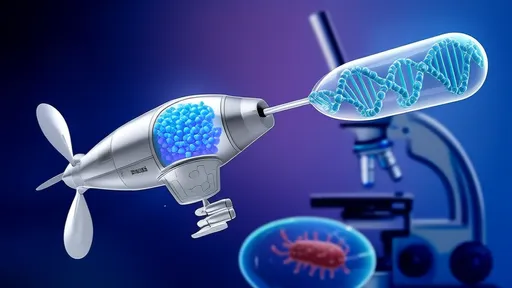

The implications for industrial chemistry are profound. Pharmaceutical companies report that autonomous systems can reduce development time for new synthetic routes by 50-80%. In one notable case, a robotic chemist optimized a palladium-catalyzed coupling reaction in just three days - a process that typically requires weeks of iterative testing. The system not only improved yield but discovered an unconventional solvent mixture that human chemists had overlooked due to preconceived notions about solvent compatibility.

What makes these systems truly remarkable is their ability to handle the inherent complexity of chemical reactions. They simultaneously optimize multiple variables including temperature, concentration, catalyst loading, and reaction time while accounting for non-linear interactions between these parameters. The robots don't just find local optima - they explore the entire experimental space to identify globally superior conditions.

Academic laboratories are also benefiting from this technology. Several universities have established autonomous chemistry platforms where graduate students submit reaction proposals that the robotic systems then explore. This allows human researchers to focus on conceptual advances while the machines handle the tedious optimization work. Early results suggest this division of labor leads to both faster discovery and more creative synthetic strategies.

The technology does face significant challenges. Reliable robotic handling of diverse chemical materials remains difficult, particularly for solids and air-sensitive compounds. There's also the question of how to properly validate machine-proposed reaction mechanisms that may defy conventional chemical wisdom. Some researchers express concern that over-reliance on autonomous systems might lead to erosion of fundamental chemical intuition among students.

Looking ahead, the next generation of robotic chemists will likely incorporate even more advanced features. Researchers are working on systems that can autonomously repair or modify their own hardware when detecting performance issues. Others are developing platforms that combine synthesis optimization with downstream purification and analysis in fully integrated workflows. As these technologies mature, we may see entire research papers where the experimental work was primarily conducted by machines with human scientists serving more as supervisors and interpreters.

This shift toward autonomous chemical research raises important questions about intellectual property and scientific credit. If a robot discovers a novel synthetic route without explicit human direction, who owns that discovery? How should authorship be attributed in publications resulting from largely autonomous research? These questions are sparking lively debates in both academic and industrial circles.

Despite these unresolved issues, the potential benefits are driving rapid adoption. Chemical manufacturers see autonomous optimization as a path to greener processes with reduced waste and energy consumption. The ability to quickly adapt synthetic routes based on raw material availability could make supply chains more resilient. As the technology continues to improve, robotic researchers may become as commonplace in chemistry labs as NMR spectrometers are today.

The rise of robotic experimenters represents more than just another automation trend - it signals a fundamental change in how chemical research is conducted. By combining the pattern recognition and optimization capabilities of AI with the precision of robotic systems, we're entering an era where chemical discovery can happen at unprecedented speeds. The human role isn't disappearing, but it is evolving toward higher-level conceptual work while machines handle the details of experimental optimization.

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025