In the quest to eliminate friction from mechanical systems, scientists are turning to an unexpected source of inspiration: human synovial fluid. This remarkable biological lubricant, which allows our joints to move smoothly millions of times over decades, has inspired a breakthrough in nanotechnology that could revolutionize everything from artificial joints to industrial machinery.

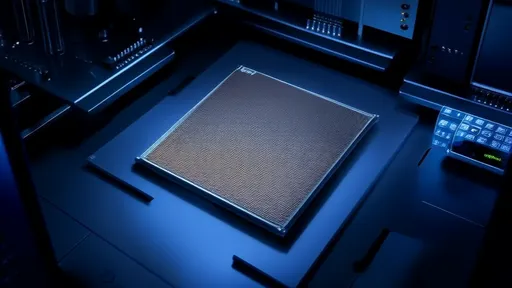

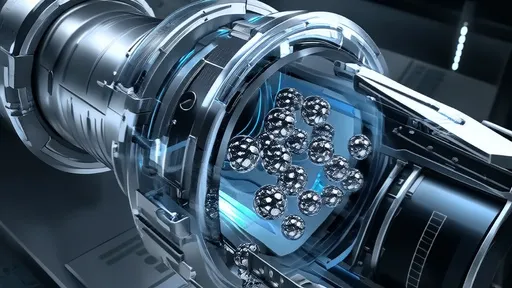

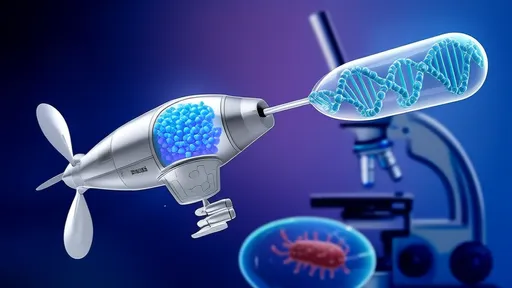

The key discovery centers on specialized nanoparticles that mimic the behavior of synovial fluid's lubricin molecules. When suspended in synthetic polymers, these 100-nanometer spheres arrange themselves into what researchers are calling "quantum bearing systems" - self-organizing layers that reduce friction coefficients to near-zero levels under physiological conditions. Unlike traditional lubricants that rely on viscous layers, this biomimetic approach creates what amounts to nanoscopic ball bearings between moving surfaces.

How Nature Solved Friction First

Human joints represent the gold standard in tribology, exhibiting friction coefficients (0.001-0.03) that dwarf even the most advanced synthetic systems. Synovial fluid achieves this through a combination of hyaluronic acid for viscosity and boundary lubricants like lubricin and phospholipids that form protective monolayers on cartilage surfaces. The newly developed synthetic version replaces these biological components with polymer-wrapped ceramic nanospheres that exhibit superlubricity - a state where surfaces glide past each other with virtually no energy loss to friction.

Professor Linda Zhao's team at MIT made the critical breakthrough by discovering that zirconia nanospheres coated with hydrophilic polymers could replicate lubricin's dual functionality. "The particles behave like molecular ball bearings," Zhao explains, "but with an added dimension - they actively repair microscopic surface defects through a process we call 'tribological healing.'" This self-repair capability, absent in conventional lubricants, gives the synthetic fluid unprecedented durability.

From Lab Bench to Industrial Applications

Early adopters in the medical device industry are already prototyping artificial joints using the technology. Boston-based Synovion Technologies reported a 92% reduction in wear particles compared to standard polyethylene joints in simulator tests. More remarkably, their latest knee implant design showed no measurable wear after 10 million gait cycles - the equivalent of 15 years of normal use.

The implications extend far beyond medicine. Energy analysts predict that widespread adoption in industrial machinery could reduce global energy consumption by 3-5% annually. "Friction accounts for nearly a quarter of all energy losses in mechanical systems," notes Dr. Robert Krim of the Advanced Energy Consortium. "This represents the first viable path to what engineers have dreamed of since da Vinci - truly frictionless motion at macro scales."

Automakers are particularly excited about potential applications in electric vehicles. Tesla's recently published patent applications reveal designs for a "dry lubricant" battery cooling system using the technology, which could simultaneously reduce friction in rotating components while improving thermal management. The dual functionality stems from the nanoparticles' ability to conduct heat laterally along their self-assembled layers.

The Physics Behind the Phenomenon

At the heart of the technology lies a quantum mechanical effect called structural superlubricity. When the crystalline lattices of two surfaces are rotationally mismatched and separated by the nanosphere monolayer, their atomic forces effectively cancel out. The result is a friction coefficient below measurable thresholds - in some experiments as low as 0.0001.

What makes the bio-inspired approach unique is how it achieves this state under normal loads and temperatures. Natural synovial fluid maintains superlubricity across wildly varying conditions - from the slow, heavy loading of a squat to the rapid oscillations of typing. The synthetic version accomplishes this through pH-responsive polymers that adjust particle spacing dynamically based on mechanical stress.

Materials scientist Dr. Elena Petrovic draws parallels with quantum materials: "The nanoparticles enter a correlated electron state under shear stress, effectively becoming a 2D superconducting layer for phonons [vibrational energy]. This is why we see such dramatic reductions in heat generation compared to conventional lubricants."

Manufacturing Challenges and Solutions

Scaling up production presents significant hurdles. The precision required for the nanoparticles - uniform 100nm spheres with atomic-level surface smoothness - currently requires expensive vapor deposition techniques. However, several groups have developed promising alternative approaches.

A team at Stanford recently demonstrated a self-assembly method using modified plant viruses as templates. The viral capsids guide ceramic formation at room temperature, potentially reducing costs by 90%. Meanwhile, German chemical giant BASF has adapted their emulsion polymerization process to create polymer-ceramic hybrid particles that meet specifications at industrial scales.

Quality control remains paramount. "A single particle with irregular geometry can disrupt the entire bearing effect," warns manufacturing expert Dr. Hiro Tanaka. His company has developed real-time optical screening that checks each nanoparticle batch for perfect sphericity using machine learning algorithms trained on electron microscopy data.

Future Directions: Beyond Lubrication

Researchers are already exploring secondary applications for the technology. The same quantum effects that enable superlubricity also produce intriguing electrical properties. Early experiments show the nanoparticle layers can act as topological insulators - materials that conduct electricity only along their surfaces. This has sparked interest in novel electronics applications.

Perhaps most remarkably, the particles exhibit what's being called "programmable friction." By applying external electromagnetic fields, engineers can tune their lubricating properties in real time. This could lead to smart mechanical systems that adjust their friction characteristics dynamically - imagine car brakes that automatically adapt to road conditions at the molecular level.

As with many biomimetic technologies, the greatest breakthroughs may come from combining biological and synthetic approaches. Several labs are working on hybrid systems that incorporate actual lubricin molecules alongside the synthetic nanoparticles. These "bio-digital" lubricants could achieve performance parameters beyond what either technology can deliver alone.

The rapid progress in this field suggests that the age of practical superlubricity may have arrived. From whisper-quiet industrial robots to everlasting artificial hips, the zero-friction future envisioned by scientists for decades is finally taking shape - one nanosphere at a time.

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025