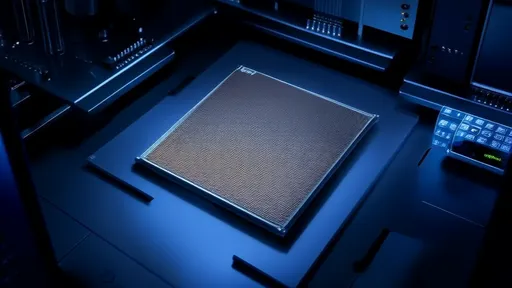

In a groundbreaking development for renewable energy and material science, researchers have unveiled a self-healing solar paint embedded with microencapsulated photosensitive agents. This innovative coating promises to revolutionize the durability and efficiency of solar panels by autonomously repairing cracks and scratches that typically degrade performance over time. The technology harnesses the power of sunlight to trigger a chemical healing process, effectively extending the lifespan of solar infrastructure while reducing maintenance costs.

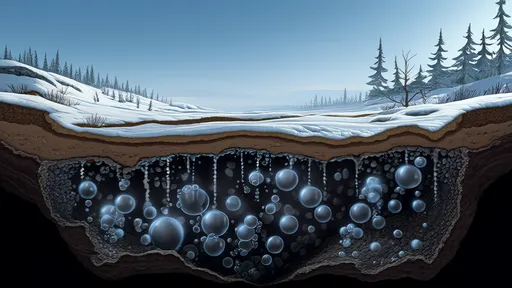

The concept of self-repairing materials isn't entirely new, but its application in photovoltaic systems marks a significant leap forward. Traditional solar panels suffer from microscopic damage caused by environmental factors such as hail, thermal cycling, and UV degradation. These imperfections may seem insignificant but collectively reduce energy output by up to 20% annually. What makes this solar paint remarkable is its ability to detect and mend these flaws without human intervention, maintaining optimal light absorption throughout its operational life.

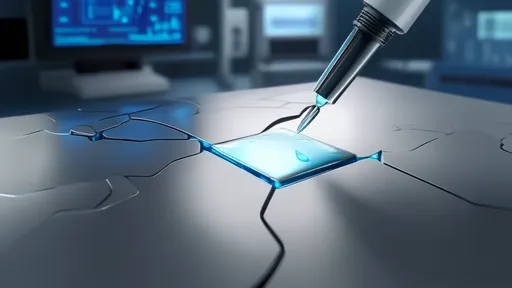

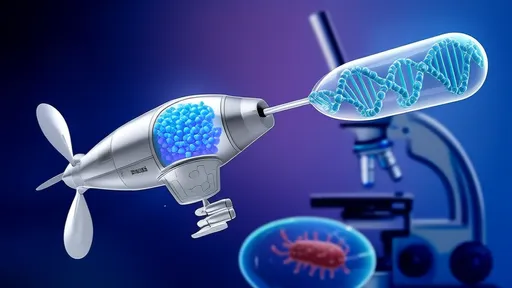

At the heart of this technology lie microscopic capsules filled with light-sensitive healing agents. When the paint's surface sustains damage, these capsules rupture and release their contents into the cracks. Exposure to sunlight then initiates a photochemical reaction that bonds the healing compounds, seamlessly filling the gaps. This process mimics biological systems where wounds trigger automatic repair mechanisms. Unlike conventional coatings that require manual reapplication, the solar paint can undergo multiple healing cycles, making it particularly valuable for installations in remote or hard-to-access locations.

Field tests have demonstrated impressive results. Solar panels treated with the self-healing paint maintained 98% of their original efficiency after 18 months of exposure to harsh desert conditions, compared to 82% for standard panels. The microcapsules' size and distribution have been carefully engineered to ensure they don't interfere with light absorption when intact. Researchers achieved this balance by using polymer shells that become transparent upon curing, allowing uninterrupted photon capture even in repaired areas.

The environmental implications extend beyond improved efficiency. By prolonging solar panel lifespan, this technology could dramatically reduce electronic waste in the renewable energy sector. Current estimates suggest that global solar panel waste will reach 78 million tons by 2050. The self-healing properties also minimize the need for toxic sealants and protective coatings typically used to mitigate weather damage. Furthermore, the paint's formulation avoids heavy metals and volatile organic compounds, addressing longstanding concerns about the solar industry's environmental footprint.

Manufacturing scalability remains a key challenge. While laboratory prototypes show promise, mass-producing the microencapsulated photosensitive agents requires precision engineering to maintain consistency across large batches. Several companies have partnered with research institutions to develop industrial-scale production methods. Early cost projections indicate the self-healing paint could add just 5-8% to overall panel expenses while delivering 30-40% greater lifetime value through sustained performance and reduced replacement needs.

Architectural applications are also being explored. The solar paint's versatility allows application on curved surfaces and building-integrated photovoltaics where traditional rigid panels prove impractical. This opens possibilities for entire cityscapes to become energy-generating surfaces without aesthetic compromises. Some prototypes even incorporate color-tuning capabilities, enabling architects to match solar surfaces with design schemes while maintaining energy efficiency.

As climate change accelerates the transition to renewable energy, such innovations address critical barriers to solar adoption. The self-healing solar paint not only improves technical performance but also changes the economic calculus of photovoltaic systems. With continued refinement, this technology may soon become standard in solar farms, urban infrastructure, and even consumer products. The research team anticipates commercial availability within three to five years, potentially coinciding with next-generation perovskite solar cells to create ultra-durable, high-efficiency photovoltaic systems.

The development underscores a broader trend in material science: drawing inspiration from biological systems to create sustainable technologies. Like plant leaves that repair themselves after damage, this solar coating represents a convergence of nature's wisdom and human ingenuity. As research progresses, we may see entire ecosystems of self-maintaining renewable energy infrastructure, significantly reducing our reliance on manual upkeep and resource-intensive replacements.

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025

By /Aug 5, 2025